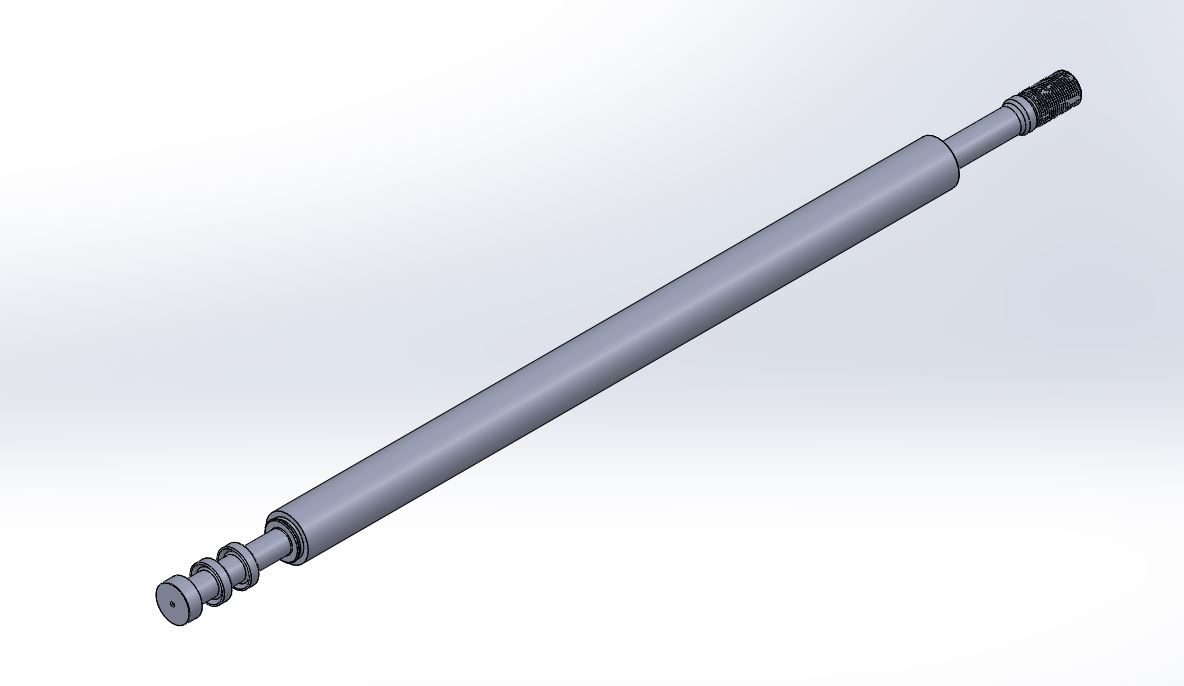

Piston Rods

Piston Rods

At Globagon, piston rods are manufactured to exacting standards, with full customization based on client-provided drawings, material requirements, and performance criteria.

All production processes, including forging, thread rolling, carbide coating, and final precision machining, are performed to ensure full control over quality and consistency.

These components are built to withstand high tensile loads while maintaining precise axial alignment and surface integrity throughout operation. Their resistance to bending, fatigue, and wear makes them critical to the reliable function of piston–crosshead assemblies under continuous stress.

By combining advanced machining technology with rigorous dimensional and surface quality control, Globagon ensures every piston rod meets the mechanical demands of modern reciprocating compressors with long-term operational reliability.

Working Principle

Piston Rods

The piston rod serves as the connecting element between the crosshead and the piston, enabling the transmission of mechanical power to the piston. The toughness of the material used in manufacturing the piston rod is of critical importance, as it ensures the component can withstand and mitigate applied pressures and vibrations. The design process begins with finite element simulations to calculate the static displacements and internal stresses within the piston rod. Following the identification of critical points, fatigue analysis and service life estimation are performed. Finally, considering the operational conditions and relevant standard requirements, the material type, its chemical composition, and the specific surface coating are selected accordingly.