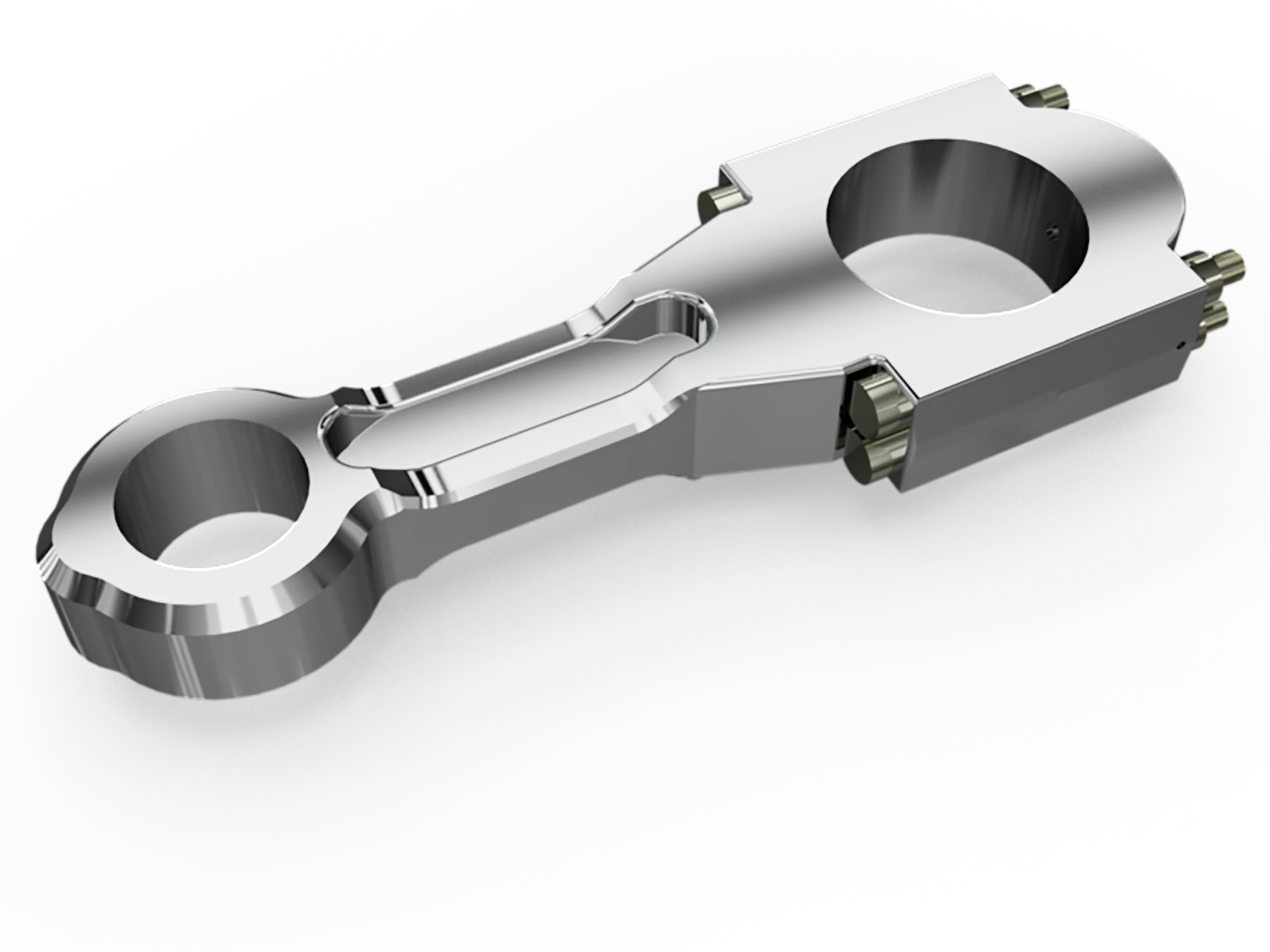

Compressor Connecting Rods

Industrial Compressor Connecting Rods

Globagon’s precision-forged connecting rods are built to withstand extreme mechanical loads and harsh operating conditions. Designed for superior strength, balance, and long-term durability, they ensure reliable performance in continuous heavy-duty applications. With excellent fatigue resistance and dimensional accuracy, they support smooth, efficient compressor motion—reducing wear and extending component lifespan.

Working Principle

Connecting rods are among the most critical components in a reciprocating compressor, tasked with converting the reciprocating motion of the piston into rotational energy at the crankshaft. This seemingly simple linkage endures some of the highest mechanical stresses in the entire compressor system—often under extreme operating conditions involving high temperatures, pressures, and fluctuating loads.

The connecting rod forms the crucial bridge between the piston and the crankshaft, transmitting force with every stroke of the compressor. It experiences both compressive and tensile forces during each cycle, and these forces reverse direction rapidly as the piston changes direction. This means that the rod must not only be strong but also flexible enough to absorb dynamic loads without deforming or failing over time.

Due to their high-speed operation and exposure to cyclic stresses, connecting rods are subject to fatigue-related wear, which can eventually lead to cracking, deformation, or catastrophic failure if not properly designed and maintained. To mitigate this, engineers pay close attention to material selection, surface treatment, dimensional precision, and lubrication.

Modern compressors often operate at higher speeds and under more demanding conditions than in the past, placing even greater demands on the strength and reliability of connecting rods. In response, manufacturers like Globagon have focused on optimizing the metallurgy, geometry, and balance of the connecting rod to maximize durability and performance.

Ultimately, the connecting rod is far more than just a link in the motion chain—it is a precision-engineered component that directly impacts the reliability, efficiency, and longevity of the compressor. Its design reflects a careful balance between strength, weight, fatigue resistance, and manufacturability, ensuring that the rod performs consistently under the toughest conditions.

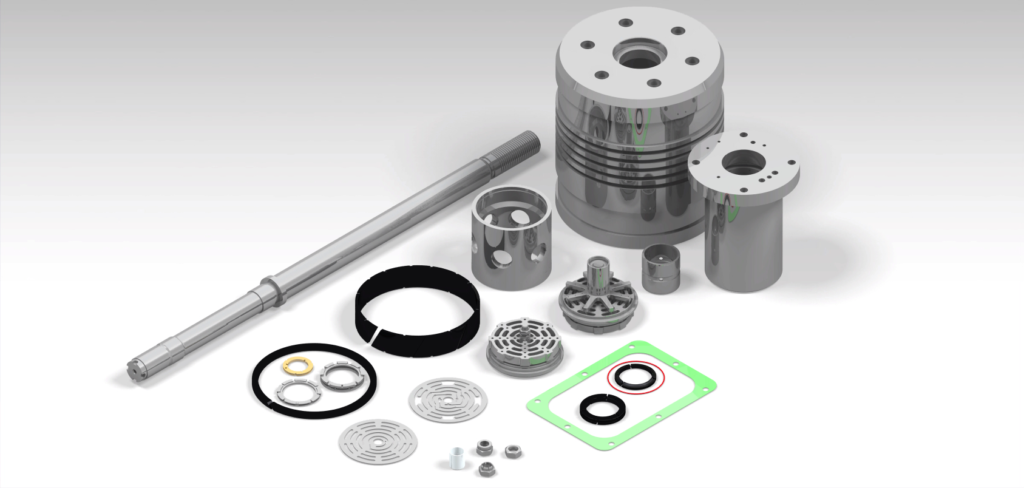

Display

Why we use Connecting Rods?

In the mechanical ecosystem of a reciprocating compressor, the connecting rod acts as the critical conduit for force transmission. Every compression cycle relies on the smooth, consistent motion of this component to convert the up-and-down movement of the piston into the rotational force needed by the crankshaft. While this may sound like a basic mechanical task, the reality is far more complex.

Dynamic Load Management

During operation, a connecting rod is subjected to rapidly alternating tensile and compressive forces—often several thousand times per minute. At top dead center (TDC) and bottom dead center (BDC), the rod endures peak loads, which can be intensified further by gas pressure in the cylinder or inertial forces due to the speed of rotation. The rod must handle these forces without yielding, stretching, or failing—often for millions of cycles over its service life.

The challenge is not just about handling high static loads, but about surviving dynamic stresses that fluctuate constantly. These repeated cycles are the root cause of fatigue failure, which often begins as microscopic cracks at stress concentration points such as the fillets, bolt holes, or bearing seats.

Material Selection and Design Optimization

Traditionally, connecting rods were made from forged steel due to its excellent strength-to-weight ratio and fatigue resistance. In modern compressors, advanced alloys—such as high-carbon steels or micro-alloyed steels—are commonly used. These materials provide improved mechanical performance, including better wear resistance and higher yield strength.

Some high-performance designs may even use aluminum alloys (in smaller, high-speed compressors) or powder metal composites. However, for large industrial applications like those served by Globagon, steel remains the preferred material due to its reliability and predictable performance under high loads.

In terms of design, weight distribution is crucial. The rod must be strong enough to withstand load, but not so heavy as to introduce excessive inertial forces. Many connecting rods are now designed using finite element analysis (FEA), allowing engineers to simulate stresses and refine the geometry—often resulting in tapered beams, optimized cross-sections, and precision-balanced ends.

Bearing Interfaces and Friction Management

The small end of the connecting rod typically houses a wrist pin bearing (connected to the piston), while the big end interfaces with the crankshaft journal through a split bearing. Both ends must allow for smooth rotation and articulation under high load and heat. Proper lubrication is essential, as metal-to-metal contact at these points would quickly lead to failure.

To improve durability, manufacturers apply surface treatments like shot peening (to relieve stress), nitriding (to harden the surface), or even specialized coatings that reduce friction and improve oil retention. Tolerances in the bearing seats are held extremely tight, often within microns, to ensure smooth operation and minimal play.

Common Failure Modes

Despite all efforts in design and material science, connecting rods are still prone to failure in certain conditions. The most common issues include:

Fatigue cracking due to repeated stress cycles.

Bearing seizure caused by oil starvation.

Bolt failure at the big end cap, often from improper torqueing.

Rod bending or deformation, typically from overloading or hydraulic lock.

Understanding these failure modes allows maintenance teams to implement preventative measures—such as regular oil analysis, alignment checks, and non-destructive testing during overhauls.

Manufacturing Excellence and Quality Control

Globagon has invested significantly in improving the quality and consistency of its connecting rods. Advanced forging techniques, CNC machining for dimensional precision, and rigorous quality checks (including ultrasonic and dye penetrant inspections) are standard in production. Every rod is balanced to ensure minimal vibration during operation, and critical surfaces are machined to tight tolerances to guarantee bearing integrity.

Additionally, traceability is now integrated into each component. Serial numbers, batch tracking, and material certificates ensure that every connecting rod can be traced back to its origin—giving operators confidence in the component’s pedigree and performance expectations.

Human Relevance and Operational Impact

For operators and technicians, the reliability of the connecting rod isn’t just an engineering concern—it has direct consequences on operational uptime and safety. A failure in the connecting rod can be catastrophic, leading to full system shutdowns, unplanned downtime, and even damage to other internal components.

Therefore, beyond just being a high-precision mechanical component, the connecting rod is a symbol of system integrity. It embodies the connection between rigorous design, dependable materials, and responsible operation. Maintenance personnel are trained to inspect rods thoroughly during service intervals, and plant managers understand the cost implications of neglecting this critical part.

Globagon’s commitment to refining and reinforcing the connecting rod reflects a broader mission: to make compressors more robust, dependable, and efficient—so that every cycle, stroke, and rotation can be trusted.