coupling

Couplings

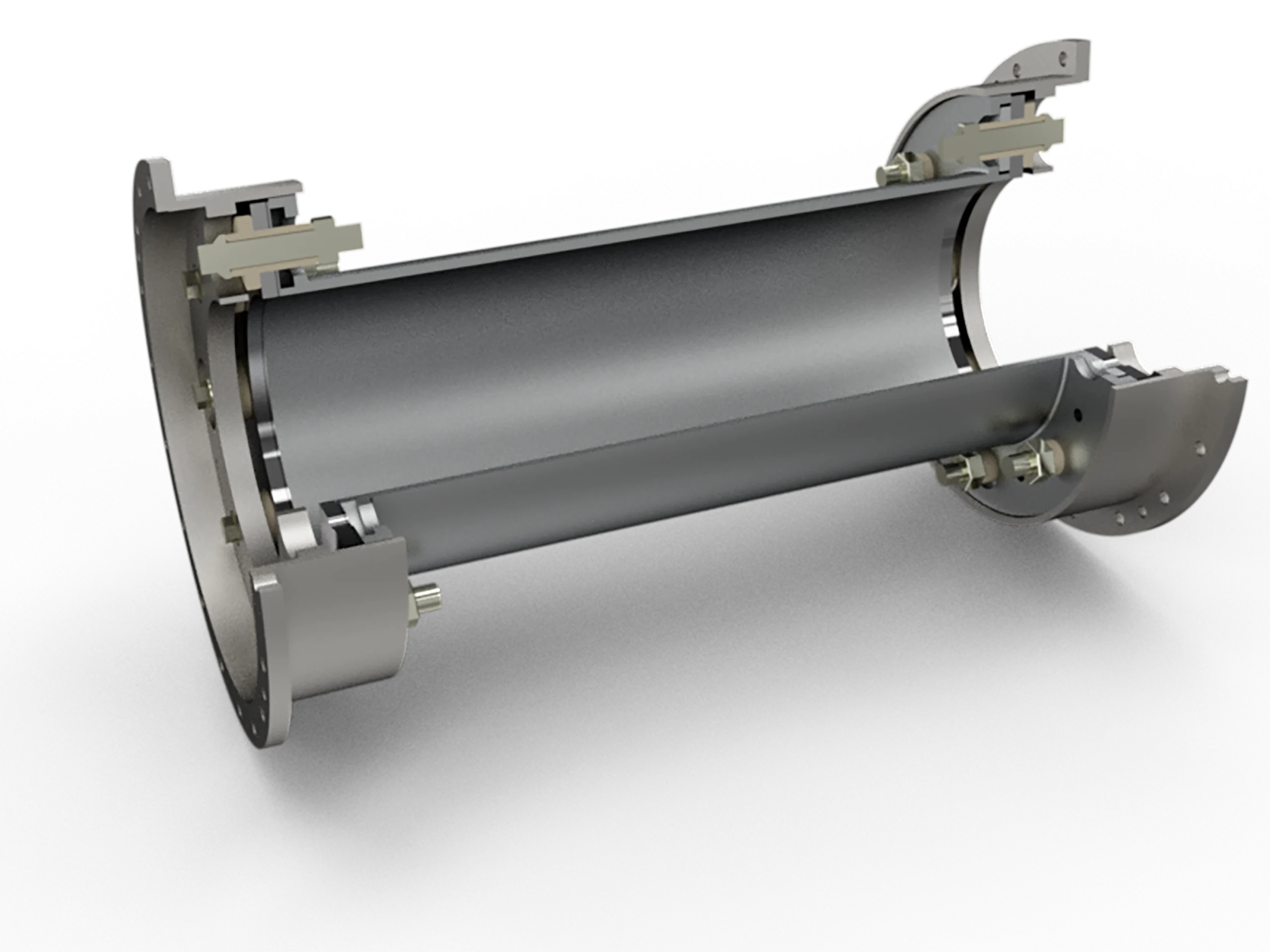

Globagon produces precision-engineered couplings that ensure efficient torque transfer between compressor and driver shafts, while controlling vibration and maintaining shaft alignment.

Our couplings are engineered to accommodate axial, radial, and angular misalignments, ensuring reliable operation even under fluctuating load conditions. They are available in both rigid and flexible types, with configurations customized to meet specific mechanical and environmental requirements.

High-accuracy machining and dynamic balancing enhance operational smoothness and contribute to longer service life of rotating equipment.

Working Principle

The suction valve coupling structure in reciprocating compressors features a piston that moves linearly within a cylinder, driven by an electric mechanism. This piston is directly welded to a valve responsible for opening and closing the internal gas flow passage, resulting in a strong, stable, and leak-resistant connection. By eliminating the need for additional mechanical linkages or fasteners, the design simplifies the overall assembly process and reduces the number of components susceptible to wear and failure over time.

This streamlined coupling structure significantly reduces dead volume—the portion of the compression chamber where gas remains uncompressed—allowing for a more efficient use of the cylinder’s capacity. As a result, stroke volume is increased, enabling a larger amount of gas to be compressed during each cycle. This directly contributes to improved overall compression efficiency and reduced energy consumption, which are critical factors in industrial applications where compressors often run continuously.

Furthermore, the rigid and precise connection between the piston and the valve enhances control over piston movement, making it easier to achieve accurate stroke adjustments and maintain consistent performance under varying operating conditions. This level of control is particularly beneficial in systems requiring high levels of responsiveness and operational stability.

In addition to performance gains, the structural integrity of the welded joint enhances the reliability and durability of the suction valve coupling over extended periods of use. This reduces the frequency of maintenance interventions and contributes to longer equipment lifespan, translating into cost savings and improved uptime for users.

Overall, this coupling approach represents a practical and efficient solution for optimizing compressor design, especially in high-demand industrial environments where performance, reliability, and energy efficiency are top priorities.

Display

Why are Couplings used?

In reciprocating compressors, the connection between the piston and the valve is more than just a mechanical joint—it is the heart of how gas enters and exits the compression chamber. Traditionally, this connection has relied on bolts, linkages, or mechanical fasteners that ensure the piston’s linear motion translates into the opening and closing of the valve. While these methods are functional, they come with a set of limitations: added complexity, wear points, potential leakage, and frequent maintenance demands.

A modern solution to these challenges is the direct welded coupling structure, in which the piston is rigidly welded to the valve. This approach creates a seamless connection, eliminating the need for secondary hardware and transforming the dynamics of compressor performance. Far from being a minor adjustment, this coupling innovation brings efficiency gains, durability improvements, and reduced maintenance that are highly valuable in continuous industrial operations.

A Seamless Mechanical Bond

The central advantage of a welded coupling structure lies in its mechanical integrity. By permanently joining the piston to the valve, engineers eliminate the small but significant weaknesses introduced by bolts, pins, or threaded fasteners. These traditional joints are prone to loosening under vibration and cyclical loading—conditions that are inherent to reciprocating machinery. In contrast, a welded joint is rigid, stable, and leak-resistant.

This seamless bond ensures that the piston and valve behave as a single unit. Every stroke of the piston is directly transferred to the valve with no delay, no slack, and no risk of misalignment. The result is precise valve timing, a critical factor in optimizing the compression process.

Simplification of Design and Assembly

Another benefit of the welded coupling is simplicity. Compressors designed with conventional couplings often require multiple intermediate parts to secure the valve in place. Each of these parts not only adds to the assembly process but also represents a potential maintenance issue down the line.

With a welded joint, the assembly process is streamlined: fewer components, fewer connections, and fewer potential failure points. This simplification translates into reduced manufacturing time and cost while improving the reliability of the final product. From a user’s perspective, fewer parts also mean fewer spare parts to manage and fewer breakdowns to troubleshoot.

Efficiency Through Reduced Dead Volume

One of the most notable engineering improvements that this coupling structure delivers is the reduction of dead volume. Dead volume is the small space in the cylinder where gas remains trapped after the piston completes its stroke. Since this gas does not undergo full compression, it reduces the overall efficiency of the system.

By welding the piston directly to the valve, the design allows for tighter clearances and a smaller gap at the end of the stroke. This minimizes dead volume, increasing stroke volume and ensuring more gas is compressed per cycle. The impact on performance is significant: the compressor can deliver more capacity while consuming less energy, making it more efficient in high-demand applications.

Precision and Operational Stability

The rigid coupling between piston and valve also enhances operational stability. In conventional designs, slight play or looseness in the coupling can cause inconsistencies in stroke length and timing, especially as components wear over time. These inconsistencies can compromise compression efficiency and lead to performance fluctuations.

The welded joint ensures precision by removing any chance of play in the coupling. Each piston stroke is executed exactly as intended, making stroke adjustments more accurate and performance more predictable. This stability is invaluable in industrial environments where compressors must respond quickly to changes in demand while maintaining consistent output.

Reliability and Long-Term Durability

Durability is another strength of the welded coupling structure. By eliminating moving or rubbing parts within the coupling, the design drastically reduces wear. The welded bond can withstand the high pressures, thermal cycles, and vibrations of compressor operation without loosening or deteriorating over time.

This robustness translates directly into reduced maintenance. Operators benefit from longer service intervals, fewer unexpected shutdowns, and lower lifetime operating costs. For industries where compressors are mission-critical—such as petrochemicals, natural gas processing, and heavy manufacturing—the reliability of this coupling can make a significant difference in uptime and productivity.

A Smarter Approach to Coupling

In summary, the welded piston–valve coupling is more than just a change in how two parts are connected—it’s an intelligent engineering decision that affects the entire performance of the compressor. By reducing dead volume, enhancing precision, simplifying assembly, and increasing durability, this coupling structure addresses multiple pain points at once.

For industrial operators, this translates into higher energy efficiency, more reliable performance, and lower maintenance costs. For manufacturers, it provides a way to differentiate compressor designs with a focus on durability and long-term value.

As industries continue to demand greater efficiency and reliability from their equipment, coupling innovations like this will play a vital role in shaping the next generation of reciprocating compressors.