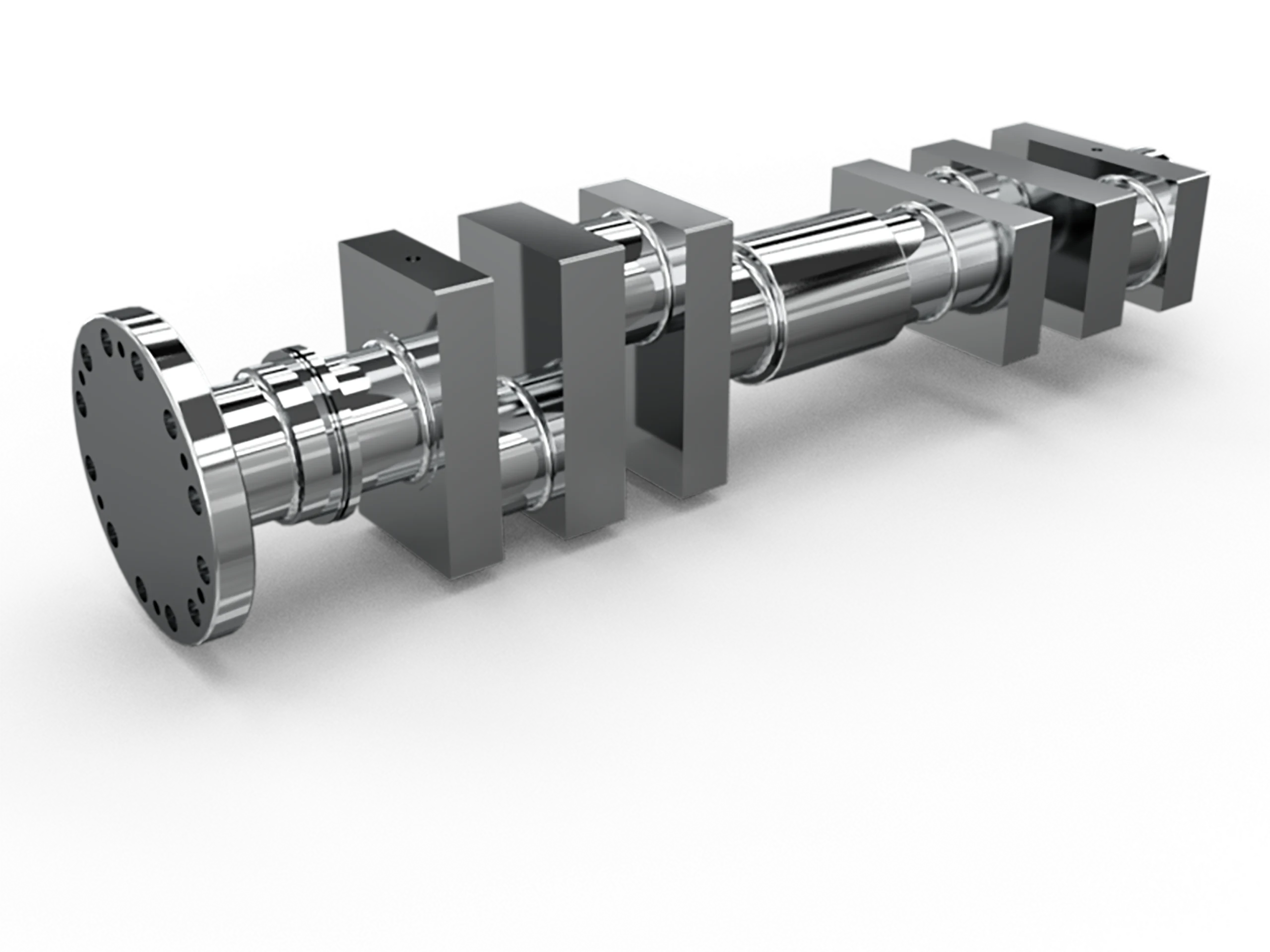

Crank Shaft

Crankshaft

Globagon manufactures custom crankshafts for reciprocating compressors, based on customer-defined specifications, load requirements, and material standards.

Each shaft is machined for maximum torsional strength, dimensional precision, and dynamic balance—ensuring smooth power transmission and long-term mechanical reliability under cyclic loading. Designs can be configured to suit various frame types, stroke lengths, and lubrication systems.

Using advanced manufacturing processes and thorough quality inspection, Globagon delivers parts that meet the mechanical and performance demands of high-duty compressor applications.

Working Principle

In larger reciprocating compressors, forged steel crankshafts are widely used due to their superior strength, fatigue resistance, and long-term durability under high mechanical loads. For smaller units rated at 150 kW or below, ductile iron crankshafts are often a more economical choice, offering sufficient performance for moderate-duty applications.

To ensure stable and efficient operation, crankshafts are typically equipped with removable balance weights. These weights are essential for correcting both rotational and reciprocating imbalances, reducing stress on other components. For compressors operating at speeds above 800 RPM, dynamic balancing of the shaft becomes critical. It helps minimize vibration, enhances reliability, and extends the service life of the entire machine.

Display

Why we use Crankshafts?

In any reciprocating compressor, the crankshaft is one of the most critical components, serving as the primary link between the driving motor and the pistons that compress gas. It converts rotational motion into the linear, back-and-forth motion required for compression. Because it operates under constant mechanical stress and cyclic loading, it must combine strength, durability, and precision engineering. The choice of material, the manufacturing method, and the balancing of the shaft all play major roles in determining compressor performance and service life.

Materials and Their Applications

The material is selected based on the size of the compressor and the intensity of its operating conditions. In large reciprocating compressors, forged steel crankshafts are the standard. Steel provides superior tensile strength and outstanding resistance to fatigue, which is critical in heavy-duty applications where the shaft must endure repeated cycles of high mechanical load. Forging also aligns the internal grain structure of the material, improving both toughness and reliability. This makes forged steel shafts the clear choice for machines expected to run continuously in demanding industrial environments.

For smaller compressors, particularly those rated at 150 kW or below, ductile iron crankshafts are often more practical. While ductile iron does not match steel’s extreme strength, it offers a balance between mechanical performance and cost efficiency. For compressors operating under moderate loads and less severe duty cycles, ductile iron provides sufficient durability while keeping manufacturing and ownership costs lower. This makes it a smart solution for mid-scale or lighter industrial applications where budget considerations play a bigger role.

The Importance of Balance

Crankshafts in reciprocating compressors are not just rotating parts—they are also subject to significant reciprocating forces as the pistons move back and forth. This creates the need for careful balancing to ensure smooth operation. To address this, shafts are equipped with removable balance weights. These weights allow engineers to fine-tune the system, correcting both rotational imbalance (caused by uneven mass distribution) and reciprocating imbalance (caused by piston movement).

Balancing reduces mechanical stresses not only on the crankshaft itself but also on surrounding components such as bearings, connecting rods, and the frame. A well-balanced crankshaft ensures smoother motion, reducing vibration and extending the life of the machine.

When compressors operate at higher speeds, particularly above 800 revolutions per minute (RPM), dynamic balancing becomes essential. Dynamic balancing takes into account not just static weight distribution but also the behavior during rotation. At high speeds, even minor imbalances can lead to excessive vibration, premature wear, or catastrophic failure. By dynamically balancing crankshafts, manufacturers achieve significantly improved reliability, smoother operation, and extended service life.

Globagon’s Expertise in Crankshaft Manufacturing

Globagon has established itself as a trusted provider of custom crankshafts for reciprocating compressors, tailoring every design to meet customer specifications. Each crankshaft is developed with a focus on strength, durability, and long-term operational stability under heavy loads. The company’s ability to adapt designs to different frame types, stroke lengths, and lubrication systems allows it to meet the needs of a wide range of compressor configurations.

The manufacturing process is centered on torsional strength and dimensional precision. Torsional strength ensures the crankshaft can resist twisting forces during power transmission, while precision machining guarantees accurate alignment of journals, throws, and counterweights. These qualities are essential for maintaining smooth operation and reducing wear across the entire compressor system.

Globagon also places a strong emphasis on dynamic balance. Every crankshaft is machined and balanced with exacting tolerances, ensuring it will perform reliably at both moderate and high speeds. This level of precision reduces vibration, minimizes energy loss, and contributes to the overall efficiency of the compressor.

Advanced Manufacturing and Quality Assurance

Modern crankshaft production requires more than just traditional machining. Globagon employs advanced manufacturing techniques to achieve consistent quality. Forging, heat treatment, precision grinding, and CNC machining are used in combination to create crankshafts that can endure the harsh conditions of industrial compressor service. Each process step is carefully monitored to maintain structural integrity and mechanical performance.

Equally important is quality inspection. Every crankshaft undergoes thorough checks for dimensional accuracy, surface finish, and balance. Non-destructive testing methods, such as ultrasonic inspection or magnetic particle testing, may be applied to detect internal flaws or cracks that could compromise reliability. This commitment to quality ensures that every crankshaft leaving the production floor is capable of meeting the highest performance and safety standards.

Reliability in Demanding Applications

The result of this engineering and manufacturing attention to detail is a crankshaft capable of delivering consistent performance over long operating cycles. In industries where compressors are often the backbone of operations—such as petrochemicals, natural gas processing, and heavy manufacturing—the reliability of the crankshaft is directly tied to the productivity of the facility. A failure in the crankshaft can cause extended downtime, costly repairs, and production losses. Globagon’s focus on durability and precision provides customers with confidence that their compressors will operate smoothly, efficiently, and reliably.

Conclusion

The crankshaft is far more than a mechanical link inside a reciprocating compressor—it is the central element that determines how effectively power is transmitted and how reliably the machine operates under stress. The choice of material, the quality of balancing, and the precision of manufacturing all directly influence performance, efficiency, and lifespan.

With its expertise in producing forged steel and ductile iron crankshafts, advanced balancing practices, and rigorous quality assurance, Globagon provides compressor users with components designed for long-term success. Whether for small-scale units or heavy-duty industrial machines, the right crankshaft ensures smooth power delivery, reduced vibration, and dependable operation—qualities that are indispensable in high-demand compressor applications.