Stuffing Boxes

Stuffing Boxes

A wide range of sizes, materials, and configurations is available to match various stuffing box designs used in reciprocating compressors. Our products are compatible with standard models or can be custom-manufactured according to your technical drawings and specifications.

Whether for replacement parts or new assemblies, Globagon delivers stuffing box components engineered for proper sealing performance, material compatibility, and dimensional precision—ensuring reliable operation under a variety of service conditions.

Working Principle

Stuffing Boxes

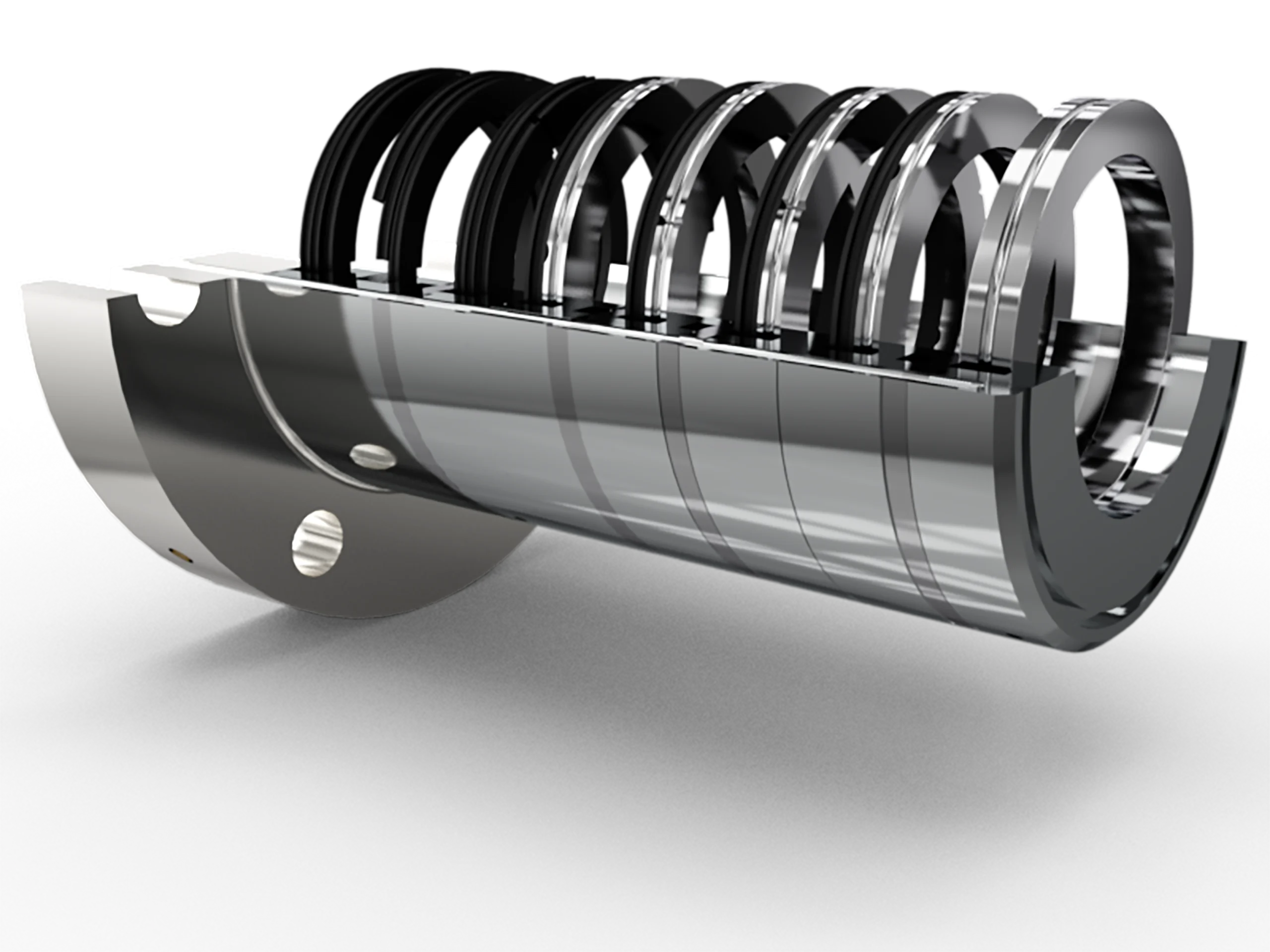

In reciprocating compressors, the piston is connected to the crankshaft via a piston rod that passes through a sealed chamber known as the stuffing box. This chamber includes a distance piece, which separates the crankcase from the compression chamber and provides space for the sealing elements.

The primary function of the stuffing box is to isolate the crankcase from the cylinder. To achieve this, specialized packing elements are installed to prevent crankcase oil from entering the compression chamber and to stop process gas from leaking back into the crankcase. This sealing system is critical for ensuring reliable compressor operation, minimizing contamination, and maintaining system pressure.